Kennametal® offers the widest selection and the most innovative designs of road maintenance tools available in the industry, including carbide grader blades, snowplow blades, and accessories.

With their expertise in highly complex metallurgy and materials science, their products are optimized for performance and significantly decrease production costs.

Teaming up with Kueper® North America, Kennametal® has made its products available to Kueper’s extensive distribution network of road maintenance products.

Key Benefits

Made in America

While most other grader blade manufacturers in the industry use carbide imported from China and elsewhere, Kennametal only uses tungsten carbide that is produced in the United States.

The reliance on U.S. – based carbide material allows Kennametal to maintain strict quality and inventory control over their grading products – ultimately leading to better customer experiences and exceptional product performance.

Grader Blade Systems

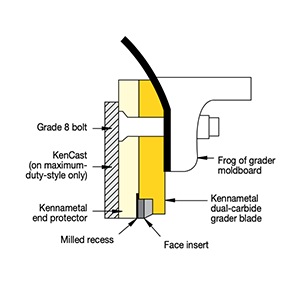

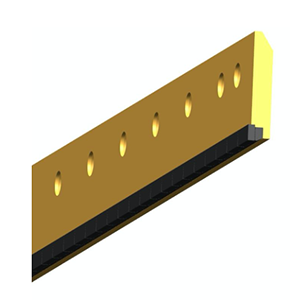

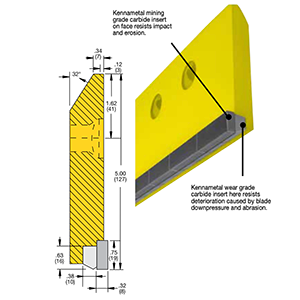

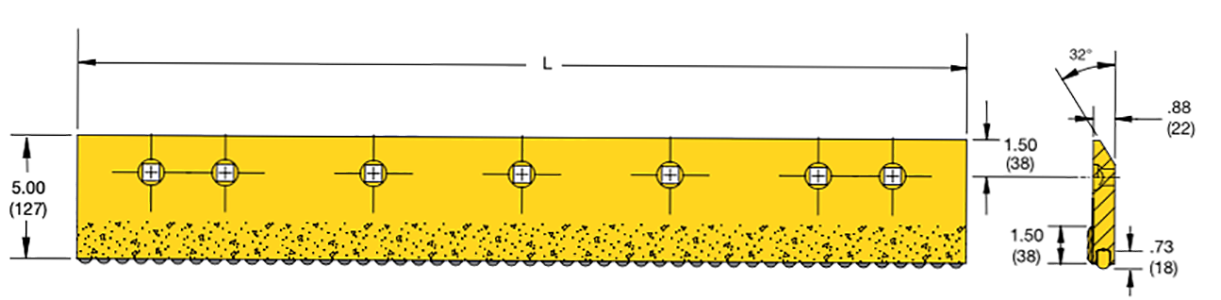

Dual-Carbide Blade System

Improved Braze, More Wear-Resistant Steel Body

Dual-carbide blades — available exclusively through Kennametal, the only manufacturer of this innovative blade — outlast embedded carbide granule-style blades. The Dual-carbide blade systems feature a universal bolt-hole and a variety of available lengths for maximum compatibility.

These tungsten carbide insert blades are specifically designed for high-abrasion applications to stay straight, maintain a sharp, clean edge, and stop crowning – ultimately providing users with the best possible finished product with the least amount of passes.

Maximum wear resistance for all gravel road maintenance applications

Dual-Carbide Blades – Two layers of tungsten-carbide: forward insert made of high-cobalt, impact-resistant, mining-grade carbide that resists impact and erosion while the second layer of wear-grade carbide insert resists deterioration caused by blade down-pressure and abrasion

Accessories

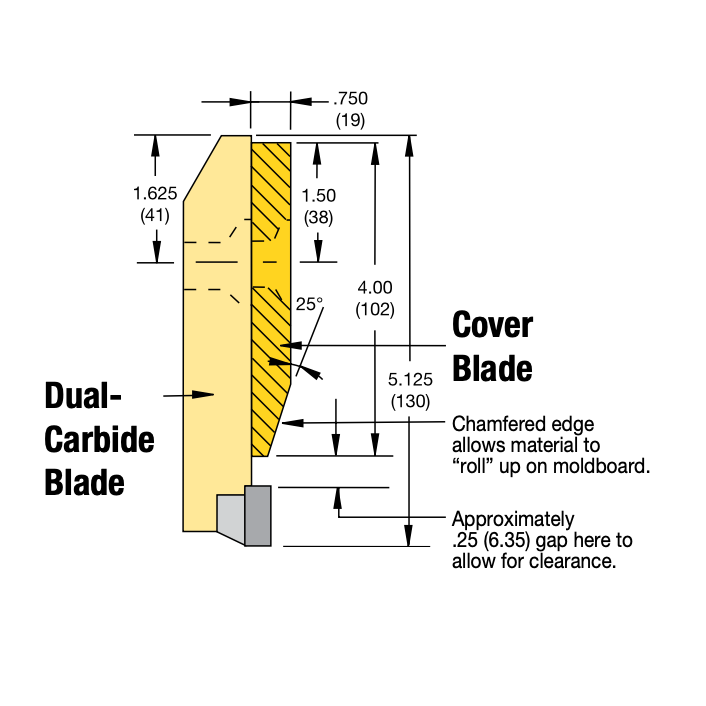

DCI Cover Blades – When operating in extremely abrasive conditions, our optional cover blades provide added wear resistance for the non-carbide portion of the blade

End Protectors – Kennametal highly recommends the use of our carbide or standard steel end protectors

-

Outperform and outlast all standard steel, embedded carbide granule style, and other carbide straight-edged styles

-

Maintain a straight edge across moldboard, even on highly crowned roads

-

Eliminates blade “curl”

-

Shorter sections are light for easier installation

WEAR FACTOR

APPLICATIONS

CONDITIONS

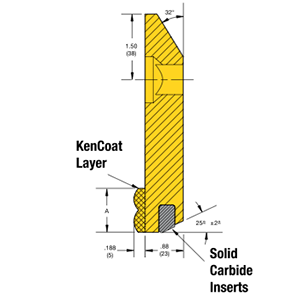

I.C.E.™/KenCoat™ Blade System

Combining Isolated Carbide-Edge (I.C.E.) Blades and Kennametal Carbide Overlay Application Technology (KenCoat)

Kennametal’s I.C.E.™/KenCoat™ blades eliminate total blade fractures and consequently provide one of the strongest carbide blades available today!

Within one blade, Kennametal® combines the durable, individually mounted bullet-shaped inserts of the I.C.E. Series™ with KenCoat™ wear-resistant carbide granules imbedded in a tough, abrasion-resistant, steel-weld material. Together, these two technologies provide the ultimate in blade strength, performance, and longevity.

-

Superior ability to break ice on compacted surfaces

-

Higher impact applications not well-suited for dual carbide blades

-

Cutting crown

-

Maintenance on hard-packed road surfaces

I.C.E.™/KenCoat™ Blades – featuring a row of .500″ (13mm) diameter, .750″ (19mm) high, bullet-shaped tungsten carbide inserts on the wear edge of the blade and a 1.50″ (38mm) wide band of KenCoat carbide in front of the inserts

Accessories

Cover Blades – Optional cover blades provide exceptional wear resistance and superior protection of the main blade body

-

Offers maximum blade strength and blade longevity — even in the harshest of road applications

-

Performs effectively to remove snow on roads with embedded lane markers and rumble strips by effectively resisting carbide fractures

-

Improved penetration compared to traditional straight-edged designs provides greater efficiency in snow and ice applications

-

Individual carbide inserts act as “teeth” to break ice

-

Fracture resistant

WEAR FACTOR

APPLICATIONS

CONDITIONS

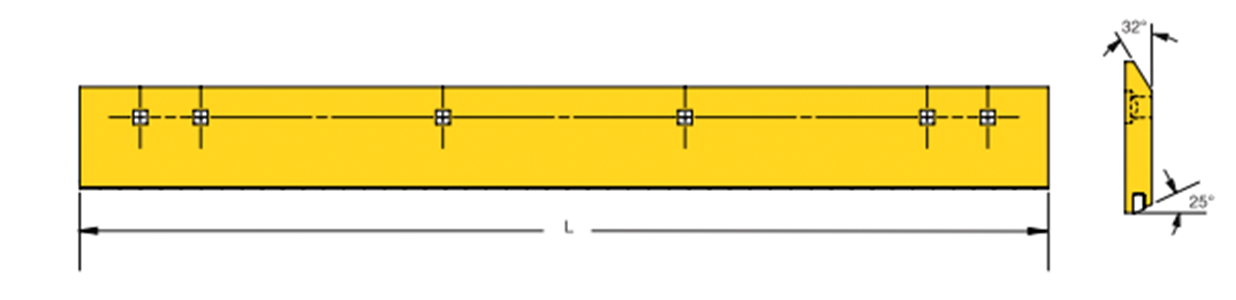

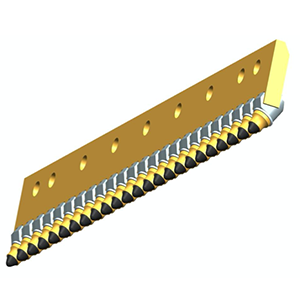

KueperXT Serrated Blade System

Serrated Steel Face with Tungsten Carbide Insert – A Kueper® North America & Kennametal® Blade Collaboration

Kueper by Kennametal XT Serrated blade uses premium Kennametal tungsten carbide, ensuring high durability and fracture resistance. Combined with a high-quality serrated steel plate that breaks up hard-packed gravel and ice, these blades provide an excellent match for modern road grading technology.

A high degree of efficiency is guaranteed through the balance of wear between the tungsten carbide and the steel body, thus ensuring the complete use of the tungsten carbide inserts in each blade. This advanced combination of wear components most notably results in quality, time, and cost advantages.

Cutting through hard-packed snow, ice, gravel, and vegetation without a scarifier system

XT Serrated Blades – Genuine Kennametal inserts formulated with macrocrystalline technology, paired with a serrated steel face designed to cut through hard-packed roads while protecting the carbide insert

-

Serrated design cuts through tough gravel pack, ice, and vegetation

-

An economical solution for year-round plowing and grading operations

WEAR FACTOR

APPLICATIONS

CONDITIONS

KueperXT Enhanced Carbide Blade System

Kennametal® Carbide Insert Grader & Plow Blades with TASSCO® Wear Plate

Kueper by Kennametal tungsten carbide blades are specifically designed for a variety of plowing and grading applications.

This blade uses premium Kennametal tungsten carbide, ensuring high durability and fracture resistance. Combined with high-quality steel, Kueper by Kennametal blades provide an excellent match for modern snowplow and grading technology.

A high degree of efficiency is guaranteed through the balance of wear between the tungsten carbide and the steel body, thus ensuring the complete use of the tungsten carbide inserts in each snowplow blade.

High-impact applications

XT Enhanced Blades – composed of Kennametal® premium carbide plow blades enhanced with Tassco XT-500 through-hardened high-performance steel, offering maximum wear life and optimal impact protection.

-

Special brazing materials resist and absorb tensile stresses and ensure a strong bond between the blade and wear plate

-

An economical solution for year-round plowing and grading operations

WEAR FACTOR

APPLICATIONS

CONDITIONS

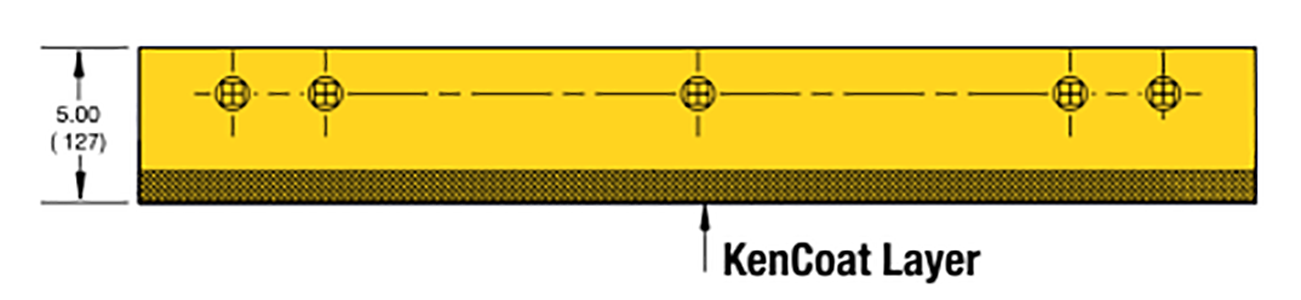

KenCoat™ Blade System

Kennametal Carbide Overlay Application Technology

KenCoat™ Grader Blades use exclusive Kennametal® Carbide Overlay Application Technology to fortify the mild steel face of standard carbide insert blades, providing enhanced blade protection and strength.

When working on unpaved surfaces, the mild steel of standard carbide insert blades often wears away, weakening the carbide insert and making it susceptible to impact and breakage. As a result, KenCoat™ Grader Blades are a cost-effective solution to prevent this type of wear.

-

An economical choice for moderate-impact applications

-

Users seeking an affordable, long-lasting blade

KenCoat™ Blades – consists of wear-resistant carbide granules embedded in a tough, abrasion-resistant, steel-weld material and protects a solid carbide insert that is brazed in place and resists wear from down pressure

-

Provides extra protection over standard carbide blade

-

Economical choices for moderate-impact application

-

Provides enhanced blade protection and resistance to wear caused by down pressure

WEAR FACTOR

APPLICATIONS

CONDITIONS

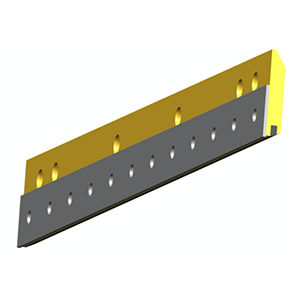

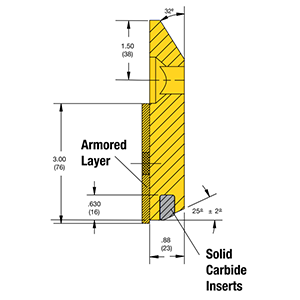

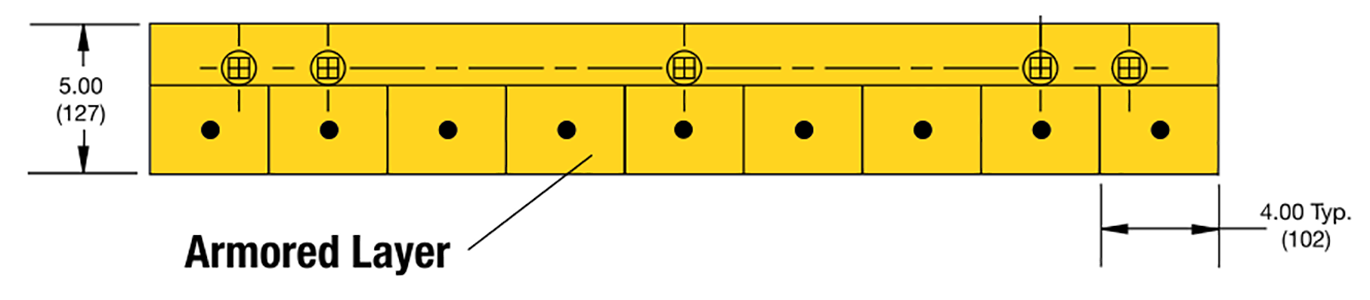

Armored Blade System

Hardened-Steel Armored Blades

Kennametal Armored Blades are designed to provide better protection of the steel face of standard carbide insert blades. When working on unpaved surfaces, the mild steel can deteriorate, exposing the carbide insert to greater impact and causing blade breakage. Kennametal Armored Blades are certainly an economical choice to prevent this type of wear.

Kennametal Armored Blades use a securely welded, hardened-steel plate to protect and further strengthen the inserts.

An economical choice with added protection for high-impact grading applications

Armored Blades – hardened steel plates spot welded to the face of the blade to provide increased protection of standard carbide blades

Accessories

Cover Blades – Optional cover blades provide exceptional wear resistance and superior protection of the main blade body

-

Designed to protect carbide insert by reinforcing the steel face with a securely welded, hardened-steel plate

-

Can be used on paved roads

-

Individual sections of the armored plate can be replaced in order to extend the life of the blade

-

Offers reduced blade wear caused by unpaved surfaces, extending blade life by three to five times as compared to a standard carbide blade

-

Economical choices for higher-impact applications

WEAR FACTOR

APPLICATIONS

CONDITIONS

Single-Insert Tungsten Carbide-Edged Blade System

Tungsten Carbide-Edged Blades for Graders with Front Plows or Wings, and Underbody Plows (Snow Removal Style)

Kennametal’s tungsten carbide-edged grader blades stand up against the toughest winter snow-packed roads. Equipped with genuine Kennametal® tungsten carbide inserts, which are secured firmly to the blade with superior brazing technique, these grader and snow blades offer unparalleled fracture and wear resistance. In fact, these tungsten carbide-edged blades are field-tested and proven to have a life span 20 times greater than competitive all-steel blades.

The Single-Insert Tungsten Carbide-Edged Blades are available in a variety of lengths in two styles: standard-size .625″ (16mm) carbide inserts and heavy-duty .750″ (19mm) carbide inserts.

Great value for dirt and gravel road maintenance in low/moderate conditions

Tungsten Carbide-Edged Snowplow Blades – Genuine Kennametal inserts formulated with macrocrystalline technology

Accessories

Cover Blades – Optional cover blades provide exceptional wear resistance and superior protection of the main blade body

-

Superior wear resistance – up to 20:1 versus steel

-

Economical choice for higher-impact applications

APPLICATIONS

CONDITIONS

Scarifier Blade System

Carbide-Tipped Cutting Tools, Blocks, and Accessories for Scarifier Blade Systems

Kennametal’s exclusive tungsten carbide-tipped cutting tools outlast all steel blades. Featuring rotating, self-sharpening cutting tools for more uniform wear and longer tool life, Kennametal blades provide exceptional cutting action in demanding, tough surfaces, including hard-packed gravel roads and frozen ground.

Blades maintain an even cutting height by enabling cutting tools to be rotated from position to position. This significantly reduces machine and operator downtime by enabling operators to individually change worn cutting tools without using special tools, and without replacing entire blade sections and bolts — within a matter of minutes.

Dirt and gravel road maintenance

Hard-packed snow and ice removal

Chip and seal road reclamation

Tar sand road reclamation

Spot asphalt milling

Spreading loose material

Mixing calcium chloride, magnesium chloride, or other dust suppressants

Scarifier Blades – Kennametal’s scarifier blade systems are designed so that just the cutting tools get replaced, not the blades

Cutting Tools and Blocks – Rotating, self-sharpening cutting tools and blocks

Accessories

Cover Blades – Kennametal’s optional cover blades provide exceptional wear resistance and superior protection of the main blade body

End Protectors – Kennametal carbide end protectors for scarifier blades feature a heavy-duty design and tough steel supports of the end protectors that resist breakage and bending in any road application

Retainers – Full-sleeve retainer protects the inside of the bore to prevent uneven wear

Extraction Tools – For removing cutting tools from blocks

Standard-Duty Blades — Ideal for light-use road grading in average conditions and applications.

Heavy-Duty Blades — Generally ideal for road grading in most conditions and applications.

Severe-Duty Blades — Ideal for grading in extreme road conditions and applications. Feature a 6″ (152mm) blade width and heavy-duty blades for more clearance between the tool holder blocks on the back of the blade and the “frog” of the moldboard.

-

Blades provide exceptional cutting action in demanding, tough surface

-

Worn cutting tools can easily be replaced in the field with minimal downtime

-

Cutting tools rotate for uniform wear

-

Easily penetrates ice and hard-packed gravel roads bringing embedded rock back to the surface

Kennametal grader blades are standard punched to fit all makes and models of graders

View Kennametal’s Grader Blades for Earth Moving and Snow Removal Product Literature for Additional Information On:

Product Specifications

Guidelines for Proper Use of Scarifier Blades

How to Replace a Worn or Broken Block

Safety Guidelines

Comprehensive List of Accessories